Rotary Die Cutters

Introducing Insignia:

a breakthrough in Rotary Die Cutting, Kiss Cutting and Converting technology from Rollem International

Insignia Die-Cutting Series Wins Printing United Alliance 2024 Pinnacle Product Award for Die-Cutting Equipment

Offer your customers high-value customized products produced in-house with Insignia die-cutters. Generate more profits from the folding carton and packaging sector.

Available in three models to accommodate various press sizes, Insignia is ideal for producing folded cartons and pocket folders, pressure sensitive products such as labels and backslit decals, garment tags, industrial applications, direct mail, invitations and other various custom shaped die cut products.

The Insignia Series is a new class of sheet-fed rotary die cutter capable of die cutting, kiss cutting, embossing, perforating, creasing and cut-scoring a range of papers, synthetic materials, films and adhesives. The X series of Insignia is specifically designed to die cut up to 30pt laminated materials for products such as school ID cards, membership cards, mailers and more.

Insignia machines are completely American built and are available with various delivery options; a StackMaster delivery unit, a PLUS touch-screen control package, a high capacity sheet stacker or variable batching options. The PLUS controls offer increased additional capabilities such as variable batch counting, barcode reading, job tracking and status reporting, operator and machine logging as well as internal hole removal capabilities and jump stripping capacity for nested die cut layouts.

Intro to Rotary Die Cutting

Key features include run speeds up to 4,500 sph, ease of operation, and quick changeover. Automatic waste removal strips out matrix. Options for delivery sections and the PLUS touchscreen control for digital print users.

The Insignia rotary die cutter eliminates sending out profitable work and allows for more control over production and turnaround times. Proudly produced in the U.S.A., Insignia is sold directly and supported by Rollem's technicians. Let Insignia change the shape of your business!

Configurations

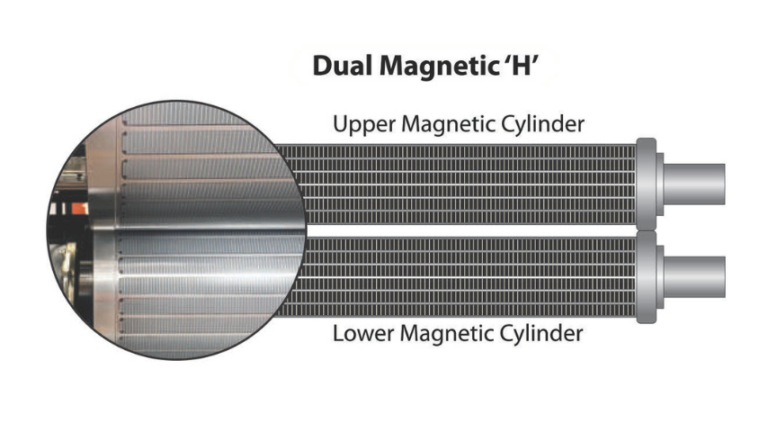

Insignia6H and Insignia7H are configured with an upper and lower Dual Magnetic cylinder design that utilizes paired sets of upper and lower dies. The H represents the ability as a hybrid system to utilize one die when only die-cutting is desired.

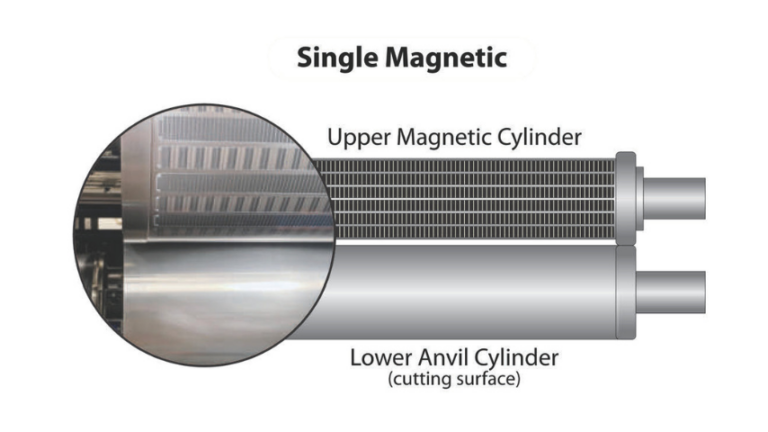

Both the Insignia6 and Insignia7 are available in a Single Magnetic configuration which utilizes a single upper die that cuts against a solid bottom non-magnetic anvil cylinder.

Speak with our representatives to discuss the ideal option based on your key product offerings.

(H) Dual Magnetic Cylinder Configuration Utilizing Upper & Lower Paired sets of Dies on both magnetic cylinders.

The Dual Magnetic H series die-cutter is designed with both upper and lower magnetic cylinders that utilize a set of male and female dies to channel score, cut, perf and emboss on the machine with absolutely no make-ready other than hanging the dies.

The Dual Mag H design is ideal for carton or pocket folder production, or for users looking to produce boxing, and other packaging products. This design can also emboss/deboss both sides of a sheet.

The H indicates a Hybrid design for finishing flexibility. When strictly cutting or kiss-cutting is required, a single upper cutting die is applied while utilizing a lower “blanket” or “jacket” die on the bottom cylinder to act as the cutting surface.

Single Magnetic Configuration Utilizing an Upper magnetic cylinder and lower non-magnetic Anvil cylinder.

The configuration of a Single Mag die-cutter utilizes a single die-tool on the upper cylinder and cuts against a precision-ground lower anvil cylinder. A single magnetic system is recommended to users who primarily produce pressure sensitive kiss-cut work, or flat cut products. This system can also perform perforating, hole punching, and cut scoring.

Both Dual Mag H and Single Mag die cutters are supplied with our automatic waste-stripping unit and a shingle delivery table. A Stack Master unit for many lanes of smaller products and a vertically-receding stacker for full sheets of products are optional delivery choices. Insignia can also be configured to operate in-line with folding/gluing units for fully automated production.

PLUS Package

The optional PLUS control package is a touch screen control with additional functionality offering batch and variable batching capabilities, internal hole removal, job status and inspection as well as other capabilities.

Insignia 6

The Insignia6 rotary die cutter’s 20×20” capacity offers the ability to feed the sheet either landscape or portrait to maximize sheet layouts. This feature saves on valuable sheet space and provides more flexibility with image impositions.

Functions include die-cutting, kiss-cutting, embossing, perforating, scoring, creasing, and hole punching, as with all Insignia models.

Insignia 7

The Insignia7 rotary die cutter is a breakthrough in die cutting and packaging technology. This new class of larger format die-cutting machine offers a B2 30×24” capacity, ideal for both offset and larger format digital presses. Insignia7 has created a distinct space in the print finishing market for rotary die cutting larger format output including folding carton and packaging applications.

Insignia X3

The InsigniaX3 rotary die cutter is designed specifically to cut materials up to 30 pt. thickness (other models handle up to 24 pt. thickness). Its wealth of value-added processes include die-cutting, kiss-cutting, embossing, perforating, creasing and hole punching. Its 24×24” sheet size adds to its feeding and layout versatility. Commercial and package printers alike are using the Insignia X3 to convert an extensive range of thick substrates.

See which Insignia is right for you.

Insignia Delivery Options

Insignia comes standard with a waste stripping unit and a slow-moving shingle belt delivery section. Optional types of delivery systems are also available:

- A high-capacity receding stacker for full sheet delivery.

- A StackMaster receding stacker with bins for smaller size, or many lanes of products.

- This IS6 shingle delivery comes standard with six belts or output lanes, and the IS7 shingle delivery comes standard with eight belts or output lanes.

- Interior holes such as a sombrero can be removed with the addition of the air blast kit.

Batching

- The machines can perform batching in two places within the system; a static batch contained in the delivery is included with each model, or a variable batch capability within the feeder that is controlled by the PLUS package which can sort based on variable quantities of product.

- A static batching system is effective for fixed quantities of product. This method is accomplished at the delivery end of the system which allows for easy quantity separation.

- A variable batching system is great for varying quantities of pieces within each order. This system relies on a printed mark as a trigger point. (part of the PLUS Package)

The waste stripping unit, used to automatically remove and deliver finished pieces from the sheet or skeleton, is included with the purchase of Insignia.

For additional information, see our detailed brochure and click on the video tab. Please reach out to our representatives to discuss the ideal option based on your key product offerings.